Airborne particles are not the most critical particles for your wafer, your optics, your medical device, your products, the most critical ones are the larger deposited particIes. Continuous and realtime detection and measurement of those particles is the only way to ensure your high quality product, your efficient and safe production. It favours people awareness and optimize the cleaning frequency..

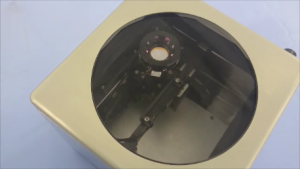

The CLEAPART-100 is an automatic device with a large – 100 cm² – collecting surface for particules. Without pump or external motion that could locally disturb the deposition phenomenon, CLEAPART-100 scans and measures from inside the contamination on the collecting surface.

Moreover, the system is set with a self-calibration system. Monitoring of either the particle deposition rate or the cumulative particle concentration is available. Resetting is carried out by software or by cleaning the collecting surface with – if possible –the same process used for cleaning your parts…

Plaquette CLEAPART100

Special Prize at CONTAMINEXPO 2015

Winlight System, CEA and CLEANSENSE have obtained the Jury special prize at CONTAMINEXPO 2015 for the DELCO, recalled today CLEAPART-100. As you may know, CONTAMINEXPO is a trade show organized every two years by ASPEC ( Association pour la prévention et l’Etude de la Contamination) on cleanrooms and contamination control.

CLEAPART-100 is an innovative, automatic and continuous detector and imager of deposited particles higher than 5 µm on a 100 cm2 static glass window.